HARVEST AND STORAGE CAN IMPACT SILAGE NUTRITION.

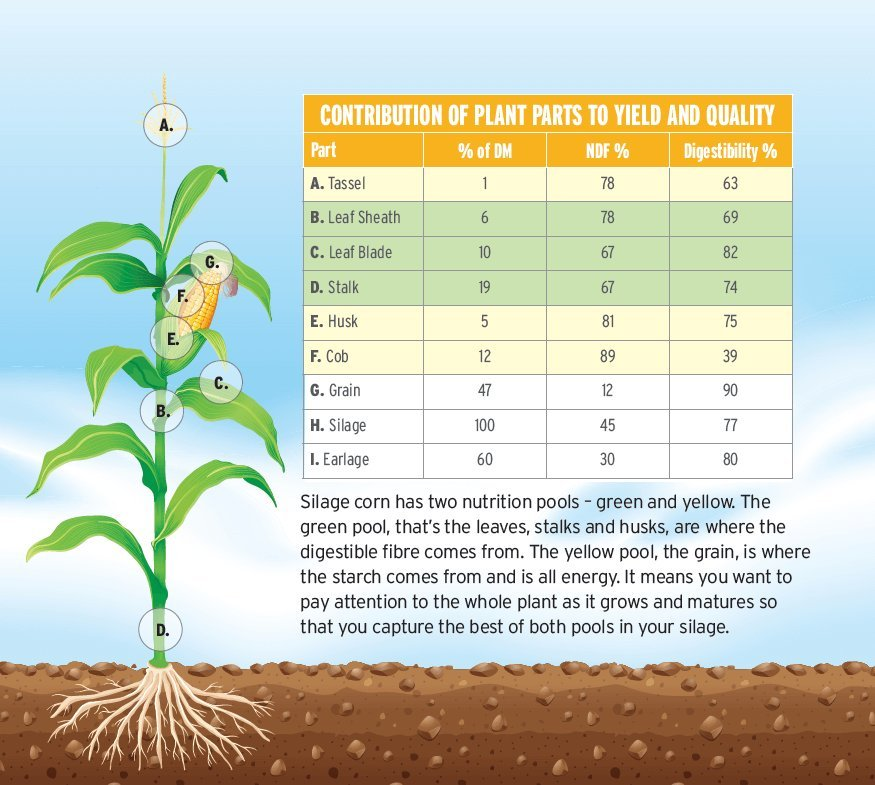

How you harvest and store silage corn can have a big impact on the nutritional value of what you eventually feed to your cattle. The sources of nutrition in silage corn are found in the green and yellow pools.

The green pool (leaves, stalks and husks) is where all the digestible fibre comes from, while the yellow pool (grain) is where starch comes from. To achieve maximum nutritional potential in both those pools, corn plants must reach physiological maturity before being harvested, which means choosing a hybrid with relative maturity (RM) and corn heat unit (CHU) ratings suited to your area. At minimum, kernels should be at the half milk line before harvesting, and whole plant dry matter is between 32 and 38% - if it's too wet or too dry it will not ferment properly.

Now that you're ready to harvest, what can you do to ensure none of that nutrition is lost?

Chop and grind. Chop plant material to the right length, and make sure your kernel processor is set to properly break apart grain and grind the cobs so that both are in a digestible form. Whole kernels in silage may have intrinsic nutritional value, but whole kernels simply pass through the rumen without releasing any of it.

Pack it, pack it, pack it. Oxygen is the enemy of successful ensiling, so the tighter you pack silage, the less oxygen there will be to create heat and alcohol - both of which diminish nutrition. The goal is to move the silage very quickly from the aerobic to the anaerobic stage, which is when lactic acid is formed to protect and preserve nutritional value. Rule of thumb: silage can never be packed too much.

Consider an inoculant. Fermentation occurs though naturally occurring bacteria that form lactic acid in the silage pile. Silage inoculants let you seed preferential bacteria into layers of silage as it's packed, speeding the ensiling process.